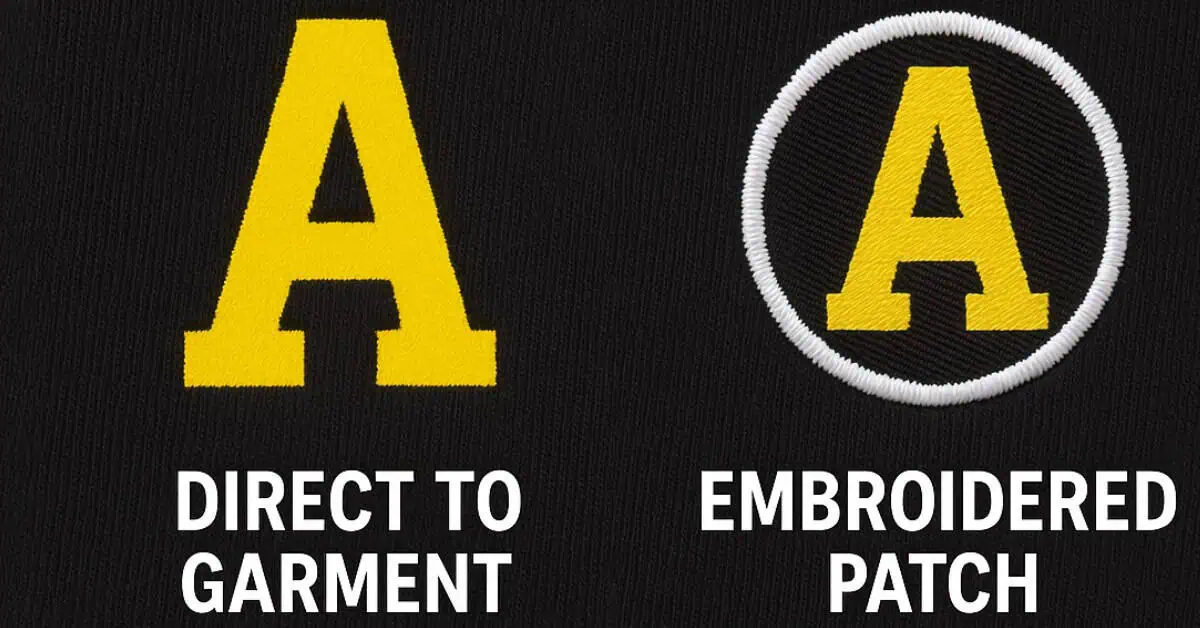

Embroidery Customization is executed in two common ways. One is directly onto the garment using the front fabric under the embroidery machine. Alternatively, embroidered patches can be created and then applied to clothing using a heat press backing, velcro hook, or stitching around. In this blog, I’ll make it easy for you to understand both clearly and choose one wisely. Let’s begin a quick side-by-side comparison.

KEY DIFFERENCE

The key difference between the two is placement. Direct embroidery is a process where the embroidery is run directly over clothing or pieces of a garment. However, an embroidery patch is created on a separate piece of fabric, which is later cut out using a laser machine or a soldering iron.

What is Better

Embroidered patches are over a hundred times better than a direct approach. Here are a few things you benefit from patches over direct machine run onto clothing.

Time Saver

Using direct embroidery you need to send all your garment stock to embroider and keep indulging in the hectic process of cropping/finishing. Whilst, embroidery patches can be easily installed in-house.

Cost Effective

With direct machine embroidery, you may need to purchase plain clothing from a different vendor and then negotiate a separate deal with an embroidery patch manufacturer, which is expensive. You might find yourself nowhere while handling your project.

Less Hectic

Buying embroidered patches is always less tiring than direct embroidery on ready-to-wear garments. You can easily avoid a lot of communication by matching the fabric color to the patch threads. When you have clothing in hand, feel yourself a King to decide desired patches. Plus, you have all your coins in hand about the sizing and placement of your favorite design onto the garment.

Easy Placement

Heat press iron-on feature shares the greatest market share of embroidery patches today. That means any custom patch you get, up to 90% is heat pressable. That means you have full control of sticking over the desired part of the sleeve, shoulder, left chest, or back of the letterman jacket.

CONCLUSION: Your project is important, and most of the time, you have a strict timeline to deliver. Therefore, embroidery-made patches are always a favorable option, as you can save a lot.