How Thermal Adhesives Work in Custom Heat-Transfer Patches

in Custom Patches, Heat Transfer Patches, Thermal AdhesiveThermal adhesive is essential for creating strong and durable bonds in heat press custom patches. When you apply heat, it activates and bonds the patch to the fabric securely. After cooling, it guarantees the patch withstands washes and everyday wear. Using the right temperature and pressure is key to activating the adhesive properly. This versatile method can enhance your projects, whether for garments or accessories. Stick around to discover more tips and tricks for effective application!

Understanding Thermal Adhesive and Its Composition

Thermal adhesive is an essential component in the world of custom patches, providing the necessary bond between the fabric and the patch itself.

Understanding its composition is key to appreciating its effectiveness. Typically, thermal adhesives are made from polymer-based materials that activate when heat is applied. These polymers create a strong, durable bond once cooled.

You’ll find various types, including polyurethane and EVA, each offering unique properties. When choosing an adhesive, consider factors like flexibility, temperature resistance, and washability.

The Heat Press Method: How Thermal Adhesive Works

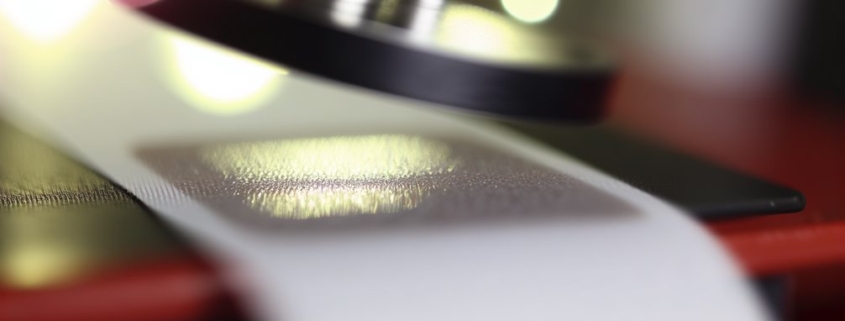

When you apply heat through the heat press method, the thermal adhesive activates, bonding the patch to the fabric. The heat causes the adhesive to melt slightly, creating a strong bond as it cools.

You’ll need to guarantee the temperature and pressure are just right; too low won’t activate the adhesive, while too high can damage the patch.

Once you’ve pressed down, let it cool before lifting the press. This process seals the edges, preventing fraying and enhancing durability.

Proper application guarantees your custom patch stays securely attached, providing the look and quality you desire for your fabric item.

Advantages of Using Thermal Adhesive for Custom Patches

Using thermal adhesive for custom patches offers several significant advantages that can enhance your projects.

First, it provides a strong bond, ensuring your patches stay securely attached, even through washes.

You’ll also appreciate the ease of application; just heat it up, press, and you’re done!

Thermal adhesive is versatile, compatible with various fabrics, and works well with intricate designs.

Plus, it’s lightweight, which means it won’t add bulk to your garments.

Finally, it’s cost-effective, allowing you to create stunning patches without breaking the bank.

With these benefits, you’ll find thermal adhesive an essential tool for your custom patch creations.

Tips for Applying Thermal Adhesive Effectively

Preparation is key to achieving the best results with thermal adhesive for your custom patches. First, verify your fabric is clean and dry to promote strong adhesion.

Cut the adhesive to match your patch precisely, then position it carefully. Use a heat press set to the recommended temperature and pressure for your materials.

Place a protective sheet over the patch to avoid direct contact with the heat source. Apply consistent pressure for the specified time, then let it cool before handling.

Finally, check the edges to confirm the adhesive has bonded securely. Following these tips will enhance durability and appearance.

Common Applications of Thermal Adhesive in Embroidery and Fabric Decoration

Thermal adhesive plays an essential role in various applications of embroidery and fabric decoration, making it a favourite among crafters and professionals alike.

You can use it to secure patches, appliqués, and embellishments, ensuring they stay in place even after repeated washes. It’s perfect for creating custom designs on garments, bags, and home textiles, giving your projects a polished look.

Thermal adhesive’s versatility allows you to bond different fabric types seamlessly, enhancing creativity in your work. Plus, it simplifies the application process, saving you time and effort while achieving durable results that withstand everyday wear.

Can Thermal Adhesive Be Used on All Fabric Types?

You can’t use thermal adhesive on all fabric types. It’s best for materials like cotton and polyester, but it may not adhere well to delicate fabrics or those with a high nylon content.

Always check compatibility first.

How Long Does Thermal Adhesive Last on Patches?

Thermal adhesive typically lasts several years on patches, especially with proper care. If you maintain your garments and avoid harsh conditions, you’ll extend the adhesive’s lifespan, ensuring your patches stay securely attached for longer.

Is Thermal Adhesive Safe for Children’s Clothing?

Yes, thermal adhesive is generally safe for children’s clothing. It’s non-toxic and designed for fabric use.

Just verify you follow the manufacturer’s instructions for application and washing to maintain safety and durability.

Can I Remove Thermal Adhesive From Fabric?

Yes, you can remove thermal adhesive from fabric. Try using heat to soften it, then gently scrape it off.

Alternatively, a solvent like rubbing alcohol can help break down the adhesive for easier removal.

What Temperature Is Ideal for Applying Thermal Adhesive?

The ideal temperature for applying thermal adhesive usually ranges from 250°F to 350°F.

Always check the manufacturer’s instructions, as different adhesives may require varying temperatures for best bonding and effectiveness during your application process.