Choosing a custom patch for chenille is not all about placement, backing options, and size – It is also about the chenille yarn, wool, acrylic yarn, etc.

We make chenille patches for personalized use in satin embroidery and chain stitch mixed. But the lifted look of fuzzy yarn has no match. (for me at least)

Well, this is just my choice I love fluffy patches. The more they stand up, feel more appealing to my viewers.

But this is not always the case, fluffiness of chenille yarn on patches varies. An initial letter on jacket in simple font is recommended higher level of chenille, while a complex artwork needs low pile so it should blossom all details.

You never know how much raised-chenile you should go to get the best out of your custom logo. It can be a little confusing to decide if you don’t know all about it.

To make this easy, I am going to unbox piles of yarn in terms of fluffiness and the amount of lift-up together in this comparison guide.

Chenille Vs Regular Embroidery

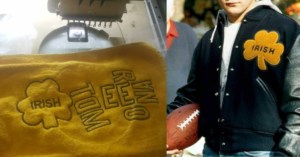

Chenille embroidery is more eye-catching as compared to regular flat embroidery. chenille is hot pick for big designs on jackets, while embroidery covers all the types of logos from workshirts to headwares.

Placement/Size

High-raised chenille embroidery looks good on big chenille patches. It works better in open areas, the bigger the design is; it comes out more elegant.

Whereas, small chenille patches fit well for low piles. Specifically, when the artwork involves text inside.

How To Make Chenille Patches

At Patches Mania, the procedure of how to create chenille patches is different for low and high piles.

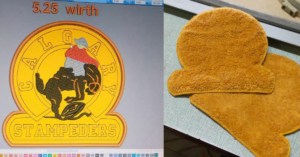

Making Low Pile Chenille Patches

For low piles, we take towel fabric which has already furry surface and embroider custom designs. This way, the thin part of design do not get lost under the piles of yarn.

When it is done from embroidery machine, it takes to cropping/cutting department for hot edges and applying required backing.

Making High Pile Chenille Patches

While making high-raised chenille patches, we use flat garment fabric. This backer fabric refers to cotton twill, synthetic felt, woven/unwoven fusing.

The next step follows sating embroidery which crates roadmap to chenille in next stage. After chenille yarn fill stitch, it moves to cutt off depart and then backing application, same way like low piles.

Guide To Use Amount Of Chenille As Per Custom Design

| Design Type | Satin Embroidery | Low Pile | High Raised |

| Mascots | 40% Embroidery | Chenille Yarn | Chenille |

| Alphabets | Outline Embroidery | NiL | Chenille Yarn |

| Numbers | Outline Embroidery | NiL | Chenille Yarn |

| Brand Names | |||

| Complex Arts | 70% Embroidery | Chenille Yarn | NiL |

| Left Breast Logos (Complex) | 70% Embroidery | Chenille Yarn | NiL |

| Left Breast Logos (Simple) | Up to 40% Embroidery | Chenille Yarn | Chenille Yarn |

| Centre Hoodies | Up to 30% Embroidery | NiL | Chenille Yarn |

| Varsity Back | Up to 30% Embroidery | NiL | Chenille Yarn |

| Biker Vest (Front) | Up to 40% Embroidery | Chenille Yarn | NiL |

| Biker Vest (Back Centre) | Up to 30% Embroidery | NiL | Chenille Yarn |

Solution

To get the most out of an order you need to check back. I highly recommend big-size patches for lifted high raised. While if your logo is small in size you need to go for low piles to get the best quality and cleaner looks.

Hope this guide makes a clear difference between both types of chenille embroidery and I wish best of luck getting thrilling quality custom patches.