Merrowed Border Patches – Features, Needs & Pricing

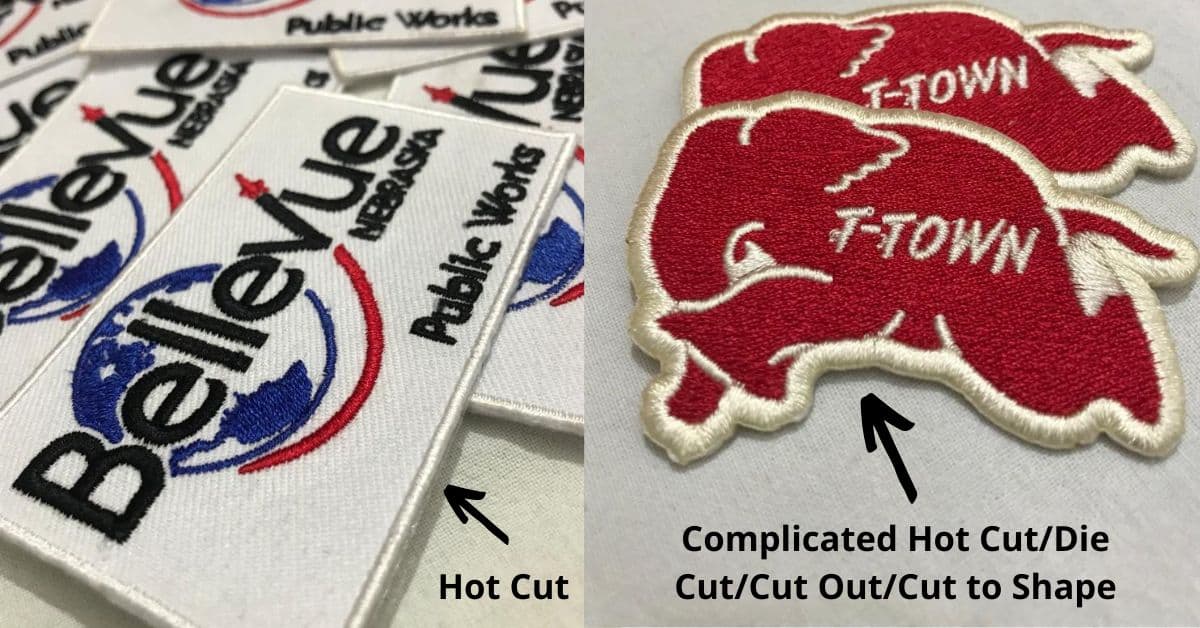

The left version shows the frame style cut-off compared to the cut-to-shape trim on the right.

If you’re fond of embroidery, you must see embroidery patches. If Yes, you can’t deny how important stitched edging is for custom embroidery.

Customized embroidery patches are an integral part of branding and promotion. If you’re one of the millions in the U.S. thinking of launching a clothing line, let me tell you the borders of machine embroidery patches play a key role in beauty. A wrong assessment can ruin the beauty of design, hence the entire project.

Luckily, I have summarized a must-consider checklist for you.

Since it’s about patches for promotion and customized needs; I won’t speak on stylish types of edging made-in-hand and crochet such as;

- Buttonhole stitch edge

- Overcast stitch border

- Blanket stitch outline

However, I would rather focus on the best-fitted patch outline of your custom embroidery patches. You will read in this blog;

- Difference between Die-Cut and Complicated

- Use of Merrow edge for Patches

- Soldering Iron/Hot Knife for Embroidery badges

- Overlock for Pvc monograms

- Cost calculator for merrow edge

Let’s begin;

Hot Cut Border

USE OF A SOLDERING IRON IS THE MOST COMMON WAY TO CUT OUT EMBROIDERY PATCHES TODAY

A hot-cut border is also referred to as a laser cut for a sharp edge that not only seals the border but also gives a stunning stitched outline to a patch. Typically, a soldering iron is used to cut off round, rectangle, square, and cut-to-shape designs.

Hot-Cut Complicated

It is when an embroidery patch is carved out following the deep inside edge-to-edge shape of the logo. Hence, it is also called “cut out”, “die-cut” or “cut to shape”.

Merrowed Edge Patch

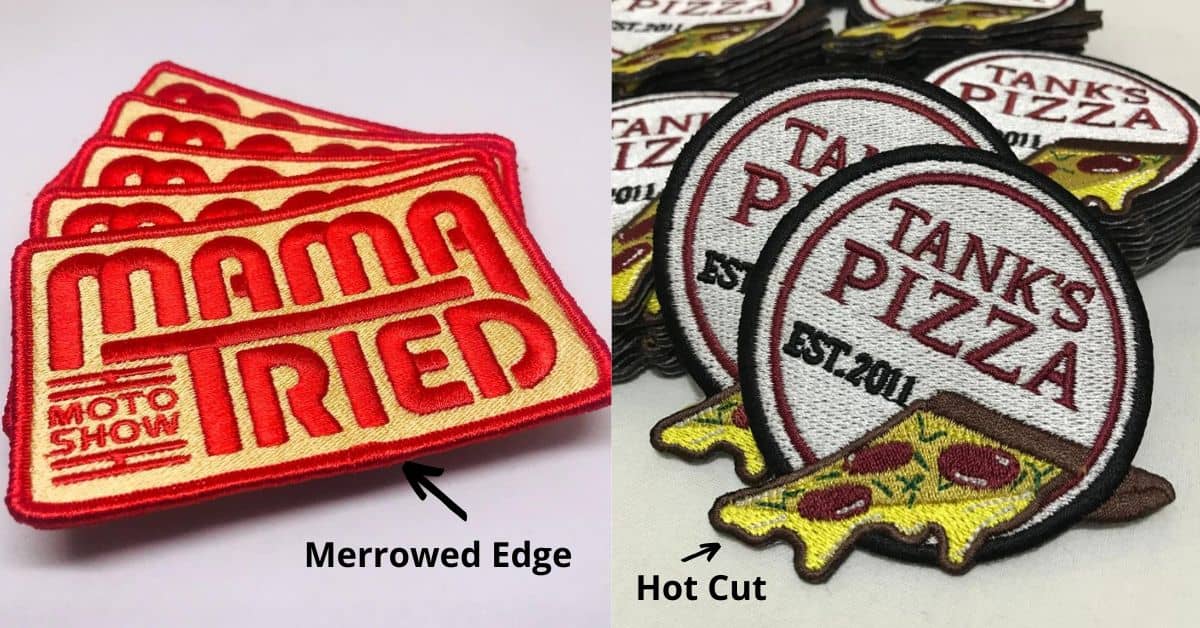

A merrowed border is also known as an overlocked or stitched lock border. The term derives from a brand machine to do this and it’s not something done by hand. It’s a complete machine procedure.

Merrow Border Patch Vs Hot Cut

FACT CHECK

- Merrow edge can not be done with complex edges/designs.

- Die cut border sublimation patch with merrowed edge works well.

- Non-merrowed patches sold cheaper than once with merrow.

- There isn’t anything that exists like the merrow border Pvc patch.

Cost Difference

Most of the embroidery manufacturers in the U.S. charge an extra amount for merrow embroidered borders, hence, it’s an elite club now.

This should be between $1 to $3 each. Luckily, it goes cheaper with the higher number of patches. Rationally speaking, if you pay $3 each additional for 25 patches, it could be as cheap as $1 for 500 patches of same size and shape.

I do believe this guidance to merrowed border patches and other types would help you a lot for your next purchase. Feel free to Team Patch Mania if you still have confusion in mind.